Spinning Mills Machine. Finisher Drawing Uster Test. Finisher Drawing Quality Check. Finisher Drawing Diagrams & Spectrograms Faults. Pakspiny

Basic sliver quality check

After the mechanical and visual checks have been completed, basic

sliver checks have to be done using the testing lab equipment to see if the

problem remains. The following can be used as a guideline to systematically

address the quality issues:

Ø Uniformity

Using an evenness tester

obtain the sliver diagram, the spectrogram and the evenness data which includes

CV%. If the drawframe has a leveler, tests should be done with both the leveler

switched “ON” and “OFF”.Compare the ON and OFF results to see if the problems

are similar or if the leveler improves the sliver.

For consistency set the sliver evenness tester to run at 50 m/min:

the maximum scale at + /- 25 %: and the paper speed at 10 cm/min. With this

setting, one cm of paper represents 5 m of sliver, and each heavy horizontal

line is a 5% change.With leveler off, look at the diagram for spikes and

obvious waves.

Ø Sliver spikes

Sliver spikes are normally

created when the roller settings are too close or possibly the break draft is

too low. Check Roller settings and fiber length and reset if necessary. Follow

the recommendations in the machine manual or in the previous section on roller

settings.It is helpful to manually feel the drafting resistance in the break

draft zone. It should be possible to press a feeler gauge into the sliver

between the first two pairs of rollers.

Ø Visible waves in the diagram

Waves that can be obviously seen in the diagram are usually caused

in the previous process or processes

Diagram showing obvious waves

The Spectrogram is most

useful in that it shows where there are periodic faults in sliver, roving or

yarn. There is an Ideal spectrogram for each type of staple fiber, and there is

a “normal” spectrogram form for each process that is slightly different from

the ideal form. In all cases the normal spectrogram should have a smooth shape

from first line at about the 2-cm wavelength, to the second line at about 6 -cm

wavelength. The curve height then gradually reduces, approaching the base line

at the 50-m wavelength.(For man made fibers the normal high point is at a

longer wavelength depending upon the staple length and staple diagram).Sliver

drafting waves extend above the normal spectrogram form and creates a hump. The

hump usually extends from 1.5 to 3 times the staple length with WL of the

highest “mean” point at about 2.25 times the staple length It should be noted

that a drafting wave hump is extended in the spectrogram by any subsequent

drafting action.

For example,

a drafting wave created in

the break draft zone would have a hump mean value of approximately 5 cm, but

which will be extended by the main draft to approximately 25 cm depending upon

the amount of the main draft. Drafting waves are caused by: Uncontrolled fibers

in the drafting zone, Short, floating fibers, Incorrect roller settings,

Insufficient drafting roller pressure, Wrong type of top roller cot Sliver mass

waves are caused by: Stretching the sliver in the process, Wrong type of sliver

funnels or condensers (inside diameter too small), Incorrect Sliver tension in

the coiling action (tension too high or too low).

Ideal and Normal Spectrogram

Break draft zone

Break draft is too low, or

Break draft rollers are too close,

Break draft rollers are too open.

Creates drafting waves in the break draft zone that are then extended by the main draft.

Main draft zone

Drafting waves can be created in the main draft zone by incorrect

roller settings, either too close or too open. The spectrogram can appear

similar in both cases.

Main draft roller distance (HVD) set too close. Staple length of

man made fibers was 38 mm and HVD = 39 mm

- Drafting system pressure

When the drafting system

pressure is not in order, the drafting action is out of control and spectrogram

waves can be seen in the range of 12 to 50 cm. This loss of control can be due

to:

- Insufficient drafting pressure.

Sliver guides incorrectly

located and compacting the slivers on one or both sides. Slivers rolling over

each other prior to entering the draft zone.Undrafted thick places that will be

seen as spikes in the sliver diagram. Leveling action waves Drafting system

pressure Loss of sliver control. The leveling action point has to be carefully

adjusted to function correctly. If the LAP is too early or too late spectrogram

waves will be visible. It is necessary to use the spectrogram when setting the

LAP.

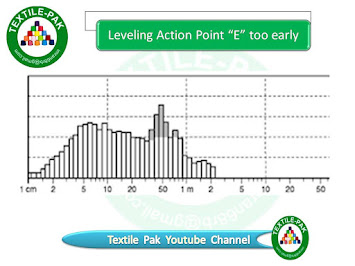

Leveling Action Point “E”

too early.

As an example, the faulty

hump has a high point at a wavelength of approximately 50 cm.

Leveling action point Too

early

Leveling action point “E” too late.Example: The faulty hump has a high point at a wavelength of approximately 30 cm.

Leveling Action Point Too Late

NOTE:

These LAP related spectrogram characteristics could appear if the sliver guides are re-justed or the sliver entry tension is changed. These actions can require a further adjustment of the LAP.

Sliver tension waves.

If the sliver tension, prior to drafting, is too low, th sliver guiding components are not effective. Slivers will roll over each other.ïSpectrogram waves can occur as break draft waves extended by the main draft or as main draft zone waves.Sliver delivery tension waves.If the delivery tension is too high the web being pulled from the delivery rolls is stretched and the sliver becomes uneven. The sliver stretching occurs at the weakest regions that coincide with the dominan drafting waves. The effect is to amplify the wave form rather than to extend the wavelength.

Coiler tension waves

If the coiler speed is not correct, the sliver will either be folded when it is too low, or it will be stretched when it is too high. When the coiler speed is too low and sliver folding occurs Spectrogram waves can be seen in the range of 1.5 to 3 cm.

This

characteristic is very evident in combed cotton.These waves can be confused

with main draft zone waves.

Spectrograms of mechanical and periodic

faults.

Coiler

Speed Corrected Combed Cotton 35 mm Mechanical faults create sliver mass

irregularities that can be seen in the spectrogram as falling into one or two

adjacent channels. These are sometimes referred to as “chimneys”. A mechanical

fault creates a defect that is then extended or drafted out by the drive

mechanisms or

by

the drafting action. By considering a specific spectrogram wavelength, the

gearing layout and the change gears used, it is possible to limit the possible

causes to one or two elements.Many periodic faults show up as a spectrogram

peak at a wavelength WL, but in addition, one or more peaks are visible as

harmonics. These harmonic wavelengths are usually at WL / 2, WL / 3, WL /4 ….

When multiple peaks are visible with this relationship, the true wavelength is

the longest one.

Draft roller defects

The following guidelines are:

Front Top Roller, Out of Round

If a roller is oval, the high and low places

occur twice each revolution and the WL in the spectrogram will then be

If the top roller cot-surface is defective the defect can show up as a 12 cm or a 6 cm peak.

Front Top Roller, Oval Shaped

Periodic faults of coiling and can filling

Trash accumulation in the coiler tube or a mechanical defect in the coiler

head can cause spectrogram spikes at the wavelength corresponding to

circumference of the coil. (WL = Coil diameter x 3.14 cm) The spikes

at the harmonics can also be visible.

False coiler peak