Drawing Sliver Coiling

When coiling sliver into the can it is important

to maintain: a smooth compacted sliver with low hairiness, fill the can in the

correct manner and minimize dust / trash accumulations in the coiler tube.

Ø Coiler tube

The form of the coiler tube

has been developed to enable the sliver to move with minimal interference into

the can. The tube is normally made of stainless steel, which is wear resistant

and suitable for most fibers. There are a very few exceptions in which the

sliver is not compatible with the frictional characteristics of steel, and will

not freely slide through the tube. In this case it may be necessary to use a

brass coiler tube.The coiler tube and plate have to be selected to suit the

sliver weight and the diameter of the sliver can.

Ø Coiler tube inside diameters

To obtain a smooth and compacted sliver the

coiler tube should be as small as practicable. If the tube diameter is too

large for the sliver, the sliver will have a tendency to:

·

Be hairy,

·

create

difficulties during withdrawal from the can,

·

have a

reduced sliver cohesion.

·

detailed

Rieter recommendations can be found in the machine manual

Ø Sliver deposit

Depending upon the sliver can size, the sliver

is coiled either “over center” in cans 225 to 600 mm diameter or “under center”

(some references use “onto the center”) in cans 800 to 1000 mm diameter.

Ø Coiler settings

To maintain good quality

coiling of the sliver, the following points of the coiler have to be correctly

set:

Coiler speed depending upon

material and sliver weight. The speed must not be excessive and stretch the

sliver, nor too slow and lay the sliver unevenly in the can location (eccentricity) to build a column

diameter 10 mm smaller than the can’s inside diameter. This should be checked

when the can is 75 % full,Can table speed to adjust the coil spacing so that

the sliver coils are side by side, not overlapping and not spaced apart.Length of

sliver in a full can must not be excessive. An overfilled can creates problems

of sliver disturbance and scuffing which leads to drafting problems at the

subsequent processes.

·

The can

condition has to correct, damaged and out-of round cans cause many problems and

a deterioration of sliver quality.

·

The cans

must be the required size and set relative to the coiler plate.

·

The can

spring length and pressure must be correct for the material being processed.

·

The

coiling conditions have to be checked and, if necessary adjusted, with any

change of: Sliver weight, - Material,

Coiler speed

Check coiler speed

The coiler speed is correct. The sliver (2)

leaves coiler plate at back of the kidney-shaped.

The coiler speed is too high. The sliver is

pulled to the inside of the coiler exit.

The sliver is stretched, the coils will be

deformed and periodic draft faults may occur.

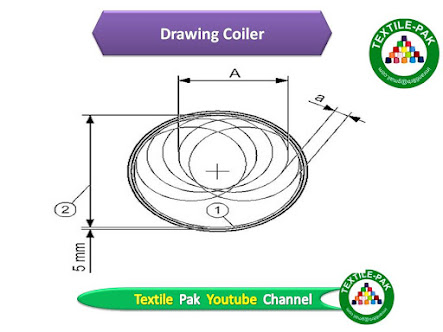

Ø Correct coiler speed

Coil

diameter (A) is evenly round. Distance (a) between the coils (A) remains

uniform around the can.The form of the sliver column (2) is evenly round and 5

mm clear of the can side (1)

Coiler

Speed Too Low

The coils

are too wavy.

The distance (a) between the coils (A) is

relatively uniform.

The Diameter of the sliver column (2) is too

large and is equal to or greater than the inside diameter of the can (1).

Ø Coiler speed too high

Sliver coils (A) are out of round and are not

consistent. The coils are drop shaped with the tip pointing toward the can

inside wall (1) The distance (a) between the coils varies from one coil to

another. The sliver column (2) is out of round. The sliver column (2) is too

small and the clearance between the column and the inside of the can is more

than 5 mm.

Coiler speed correct

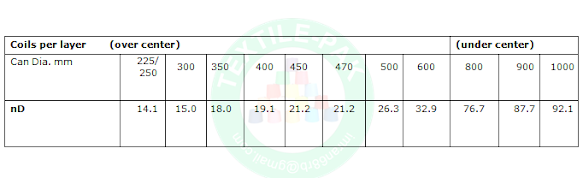

Sliver coils per can revolution

The

sliver coils per layer is obtained by dividing the speed (rpm) of the coiler by

the rotational speed of the can table. With larger diameter cans the number of

coils per layer increases to maintain optimal coiling and can filling.

nD =

Relationship of coiler rpm to can table rpm

nD =

coiler rpm

can table

rpm

The

following can be used as a guideline

Ø Can eccentricity

The outside diameter of the sliver column is primarily established by the relative positions of the centers of the coiler and the can table. This distance is referred to as the eccentricity. If the can table is moved to reduce the eccentricity the sliver column will be reduced, and conversely the column will be increased if the table is moved to increase the eccentricity. The setting of the can table eccentricity is normally not changed.

However, it may be necessary to make a re- adjustment if there is a change to fibers of greatly different bulk characteristics, such as cotton to acrylic fibers.

No comments:

Post a Comment